Jungheinrich PowerCube: compact high-bay system with shuttles. Closed bin warehouse.

The Jungheinrich PowerCube is an automated storage system with plastic bins that are placed and picked by autonomous shuttles.

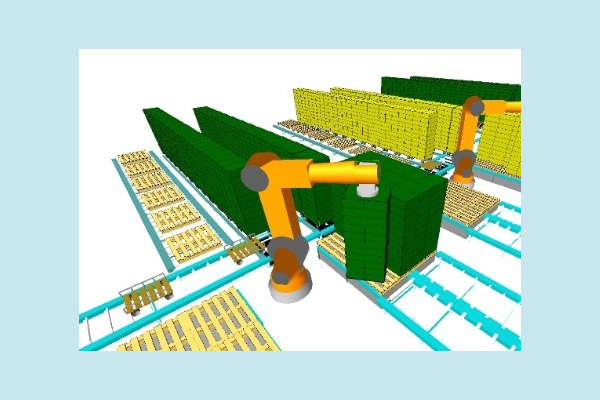

The photo shows a design of the warehouse that Jungheinrich supplied to Fastbolt in Gronau (Germany), a wholesaler of screws. This storage facility has space for 18,000 bins for small parts with a load capacity of up to 50 kilograms each. Thanks to its compact dimensions, such a high-bay system can be integrated into, for example, a larger/more diverse warehouse that also includes pallet storage.

PowerCube shuttles handle the storage and retrieval of bins. At speeds of up to 4 m/s, the shuttles can simultaneously transport two bins, each with a load of 50 kilograms, to three workstations.

The shuttles’ lithium-ion batteries are temporarily charged during use at their respective workstations, using the current collectors on the shuttle and the charging contacts on the racking system.

The PowerCube is scalable and can therefore be adapted and expanded as needed.